Kanban: More Than Just Todo, Doing, Done – Part 1

History

Kanban (看板) means “signboard” in Japanese. It was developed in the 1940s by Taiichi Ohno, an industrial engineer at Toyota, during efforts to optimize production.

Kanban aims to reduce product development time and shorten the journey from supplier to customer. This aligns with the concept of Just In Time Production.

What Is Kanban?

Core Principles

1. Visualize Work

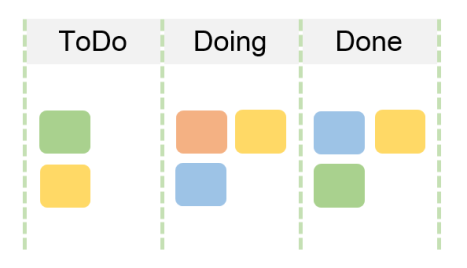

Teams visualize work using a board (physical or digital). This board displays tasks clearly so everyone can discuss, collaborate, track progress, and stay updated.

Why it matters:

- It ensures transparency, which leads to better collaboration.

- It clarifies task ownership and progress (who is doing what).

- It serves as a central tool for monitoring progress, managing priorities, and keeping everyone aligned.

2. Limit Work in Progress (WIP)

Kanban encourages teams to limit the number of tasks in progress to improve productivity.

Key terms:

- Cycle Time: Time required to complete a task.

- Throughput: Average number of tasks completed in a given time.

- Lead Time: Time from Todo → Doing → Done.

According to Little’s Law, when throughput stays constant, more WIP leads to longer processing times.

Common examples of excessive WIP in software:

- Features under development but not finished.

- Code that works locally but isn’t integrated.

- Features stuck in testing, not yet released.

Consequences of too much WIP:

- Frequent context switching wastes time and energy.

- Feedback loops shrink or break, delaying improvements.

- Risk increases.

- Team morale drops.

- Product quality suffers.

3. Manage Flow

Flow means moving work continuously through each stage without delays. In the Toyota Production System, every step adds value, from start to finish.

Flow helps teams identify bottlenecks and remove waste—anything the customer doesn’t value.

To support continuous flow, teams must:

- Ensure tasks are ready before starting them (e.g., Todo → Doing).

- Remove blockers together when someone is stuck (swarming).

- Share daily updates to stay in sync.

Summary

This part covered the fundamentals of Kanban—visualizing work, limiting WIP, and managing flow. In Part 2, we’ll explore:

- Board structure: physical vs. digital

- Time-tracking techniques (e.g., banana slips)

- Methods to enforce WIP limits

- Task classification for better prioritization and scheduling

- When and how to estimate

- Common Kanban pitfalls

Let me know if you want this version localized back to Vietnamese using the same clarity principles.